Customized Trailer k'haravene barrel le fanyeha Kit

Khamphani e ithorisa ka matla a mahlale a mahlale. Hajoale, e na le lisebelisoa tse ngata tsa machining tsa CNC, mechini e silang, mechini e hulang gear, mochini oa ho itšeha ka terata le elektrode. Lihlahisoa tsohle li rekisa hantle kantle ho naha. Bokhoni ba kantle ho naha ba k'hamphani bo fihla ho lidolara tse limilione tse 5 tsa Amerika. Ho itšetleha ka katleho e atlehileng ea mahlale le mahlale a morao-rao, k'hamphani e ile ea etsa lipatlisiso le ho nts'etsapele lihlahisoa tse ncha. Lihlahisoa tse hlahisitsoeng ke k'hamphani li kenyelletsa liase tsa koloi, linko tsa ho ohla, liforeimi tse kholo tsa likoramo, liforeimi tse nyane tsa lithaere, li-brake calipers, li-disc tsa brake, meropa e pshatlang, literela, jj.

Ho feta moo, k'hamphani e ka hula litšoantšo tsa CAD kapa 3D le ho nts'etsapele li-castings, hlobo ea tšepe, jj ho latela litlhoko tsa moreki.

Khamphani e hlahisa ka theknoloji e tsoetseng pele, taolo e thata ea boleng, le liteko tsa saense le tse thata tsa ho etsa liteko le ho latela litlhoko tsa bareki, ehlile li netefatsa boleng ba lihlahisoa mme li lula li matlafatsa khotsofalo ea bareki.

Lintlha tse potlakileng

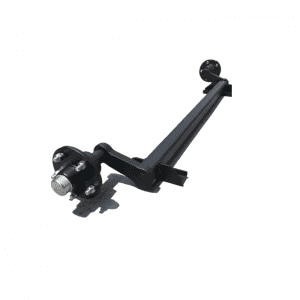

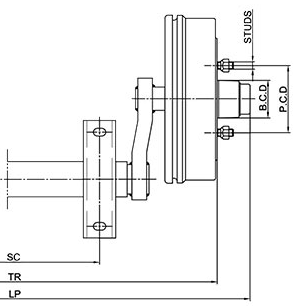

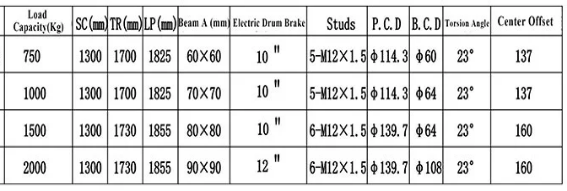

1.The axle tube e entsoe ka ho tobetsa matla a phahameng a phanele ea tšepe ka mokhoa oa ho kenella ka har'a arc weld le weld ea khase ea carbon-arc, e matla haholo, khatello e tlase, e palamisa haholo ebile e sa holofala.

The leakage radiation e ne e entsoe ka lintho tse bonahalang motsoako tšepe le tšoara ka kalafo mollo mora betloa ha tiileng. E na le ho khetheha phetolo ya sithabetse betloa ha le phahameng koba intension.

3.E hlahisitsoe ke theknoloji e tsoetseng pele ea Jeremane, moralo oa barrel o na le litokelo tsa molao mme barrel e ka kopanngoa le barrel hammoho ntle le letho le robehileng.

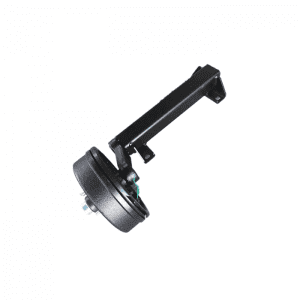

4.The behang ke bohlokoa kapa ka hare tummeng cha phahameng play loading sehlahisoa, ho ke wearable qetellong na le nako e telele bophelo. E etselitsoe hore e be theipi e ikhethang mme e ka fokotsa khatello ea maikutlo le ho eketsa tsitsipano ea mokhathala ..

Ts'ebetso e phahameng ea lipale tse iqapetsoeng tsa asbestos e fetile tlhahlobo ea Amerika, 'me e latela khoutu ea tikoloho. E na le bokhoni ba ho roala le ho robeha holimo (sensor ea ABS e ka ikhethela).

6.Camshaft e ne e thehiloe ka bongata, mochini oa taolo ea linomoro o ka sebetsana le mothinya oa S ka nepo e phahameng, bokaholimo bo ile ba tima maqhubu a mahareng mme o apere hantle.

7.The slack adjuster e ne e entsoe ea bohlokoa le Jeremane Technology, tumello e nyane mme e na le ts'epo e phahameng ea ho e sebelisa (auto adjuster e ka ba khetho)

8.Ductile cast cast wheel hub le tšepe e bohlooho kaofela li hlahisoa ho latela maemo a machabeng. ba na le bokhoni ba ho kenya lintho ka bongata, bo a khoneha, ha bo chese mocheso ebile ha bo na sekoli.

Seboka sa barrel se hlahisitsoeng ho latela maemo a machabeng, mefuta e ka sebelisoa hangata ka mofuta oa BPM mme e na le bokhoni bo phahameng ba ho fetoha, ka hona ho bonolo ho e hlokomela.

10.Tyre bolt le linate li entsoe ho latela maemo a ISO le JIS ka lisebelisoa tsa alloy, ka hona li bolokehile ebile lia tšoarella.

LBH

Q1. Ke mantsoe a hao ya paka eng?

A: Ka kakaretso, thepa e koaloa ka mekotla ea maqheka ebe e paketsoa ka mabokoseng le palleteng kapa mabokoseng a lehong.

Q2. Ke mantsoe a hao ya tefello ke efe?

A: T / T (peeletso + esele pele u pepa). Re tla u bontša linepe tsa lihlahisoa le liphutheloana pele u lefa chelete.

Q3. Mantsoe a hao a pelehi ke efe?

A: EXW, FOB, CFR, CIF.

Q4. Ho thoe'ng ka nako ea thomello ea hau?

K: Ka kakaretso, ho tla nka matsatsi a 25 ho isa ho a 60 kamora ho fumana tefo ea hau esale pele. Nako e ikhethileng ea ho tsamaisa e latela lintho le bongata ba otara ea hau.

Q5. A na u ka hlahisa ho latela disampole ho?

A: E, re ka hlahisa ka mehlala ea hau kapa litšoantšo tsa tekheniki. Re ka haha hlobo le lihlopha.

Q6. Sampole leano la hao ke efe?

A: Re ka fana ka sampole bakeng sa tefo ea mahala haeba re na le likarolo tse loketseng setokong, empa bareki ba tlameha ho lefa litšenyehelo tsa lengosa.

Q7. U etsa khoebo ea rona kamano ea nako e telele le e ntle joang?

K: Re fa bareki ba rona ts'ebeletso ea ho emisa hanngoe, ho tloha ho karolo e itseng ho ea ho lihlahisoa tsa ho qetela tse kopaneng, ho rarolla mathata a fapaneng ho bareki ba fapaneng lefats'eng lohle.